Introduction

In today’s competitive world, production speed and quality are not limited to the main machinery of your production line; auxiliary equipment, such as industrial printers, also plays a vital role in ensuring product quality, traceability, and branding. Printing information like production and expiration dates, serial numbers, barcodes, or even brand logos is an essential part of production standards. Therefore, choosing the right industrial printer is not just a simple purchase—it’s a long-term investment to improve efficiency and reduce costs.

Key Considerations for Choosing an Industrial Printer

1. Printing Speed and Compatibility with Production Capacity

One of the most important factors is ensuring the printer matches the actual speed of your production line. A printer that operates slower than the line creates bottlenecks and reduces overall efficiency.

Practical Example: In a food packaging plant producing 150 packages per minute, using a low-speed printer will cause frequent stoppages and delays in order fulfillment. Therefore, comparing the printer’s rated capacity with the actual production line speed is essential.

2. Print Quality and Type

The type of information required on your products influences the choice of printer. Some industries only need expiration dates, while others require 2D barcodes (QR Codes), logos, or variable information.

Practical Example: In the pharmaceutical industry, legible barcodes and expiration dates are legally crucial. A low-quality printer can lead to product recalls and even heavy fines.

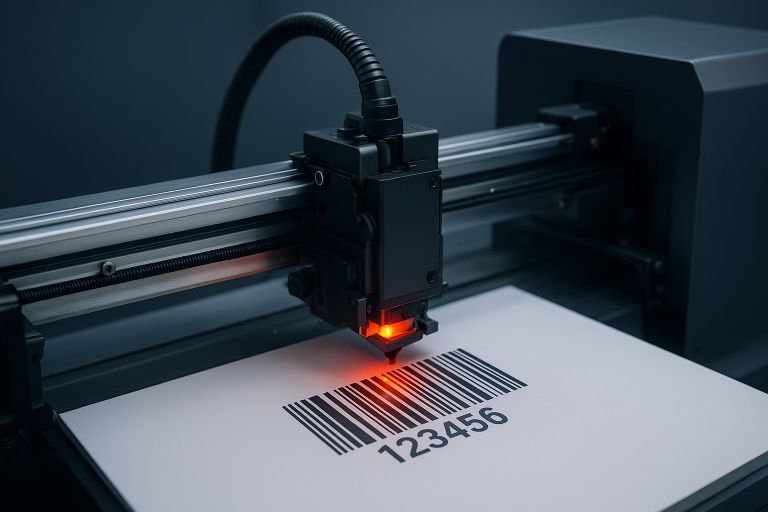

3. Choosing the Right Printing Technology

Different printing technologies offer distinct advantages and limitations:

Inkjet Printers: Ideal for fast printing on various surfaces like plastic, metal, glass, and cardboard.

Laser Printers: High quality and long-lasting without ink, but higher initial cost.

Thermal Transfer Printers: Perfect for high-resolution labels, widely used in food and hygiene industries.

Practical Example: In carbonated beverage production lines, inkjet printers are ideal due to their high speed and ability to print on wet bottles.

4. After-Sales Service and Support

Even the best machines cannot deliver their full value without reliable support. Access to spare parts, operator training, and regular maintenance is crucial.

Practical Example: An automotive parts factory faced frequent production line stoppages due to printer malfunctions and lack of support, resulting in costs far exceeding the printer’s price.

Why Choosing the Right Printer Matters

An industrial printer is more than a simple tool; it’s part of the value chain and product quality assurance. Choosing the wrong printer can lead to production stoppages, higher maintenance costs, and loss of customer trust. Therefore, selecting the right printer should be based on careful analysis of your needs, product type, and factory infrastructure.

Introducing Omega: A Trusted Partner for Iranian Industries

With years of experience in supplying and supporting industrial equipment, particularly industrial printers and marking devices, Omega has earned a distinguished position among manufacturing industries.

Omega’s Competitive Advantages:

Specialized consultation tailored to your production line

Access to various printing technologies

Fast and reliable after-sales support nationwide

Professional training for production teams to maximize device efficiency

Conclusion

Choosing and purchasing an industrial printer is a strategic decision for any factory or production unit. Considering printing speed, quality and type, suitable technology, and after-sales support ensures your investment delivers maximum return.

If you are at the stage of selecting a printer and need expert guidance, Omega’s specialists are ready to recommend the best solution for your production line. Contact us today to take an effective step toward improving productivity and product quality.